chifeng-Irregular metal parts refer to those metal parts that are irregular in shape, size, surface treatment, etc. These parts usually need to be manufactured by special machining processes, such as laser cutting, numerical control machining, stamping, etc. Irregular metal parts are commonly used in the manufacture of various mechanical equipment, electronic equipment, automotive and aerospace components.

As the manufacture of irregular metal parts is more complicated, some problems should be paid attention to in the production process, such as the selection of materials, process optimization and equipment selection. In addition, the design of these parts also needs to take into account the reliability, durability and safety requirements during use.

Irregular metal parts play a very important role in various industries, and their manufacturing process requires highly specialized technology and experience.

Polishing of irregular metal parts

Polishing of irregular metal parts

For the polishing of irregular metal parts, it is usually necessary to consider the shape of the part and the treatment of the surface. Here are some common polishing methods:

Mechanical polishing: Grinding and polishing the surface of parts by using grinding wheels and other mechanical equipment. This method is suitable for parts with regular shape.

Chemical polishing: The surface treatment and polishing of metal parts by using chemicals such as acid and alkali. This method is suitable for irregular metal parts with oxide or other stains on the surface.

Electrolytic polishing: The surface treatment and polishing of metal parts in an electrolyte by means of electrolysis. This method is suitable for irregular metal parts with high precision surface requirements.

Hand polishing: For irregularly shaped metal parts, it is usually necessary to use hand tools, such as sandpaper, polishing cloth, etc.

When selecting the polishing method, the shape, size, material and surface treatment of the parts should be taken into account. At the same time, it is also necessary to pay attention to the thermal damage and deformation caused by the parts in the process of polishing. Multiple finishes and checks are usually required to get the best finish.

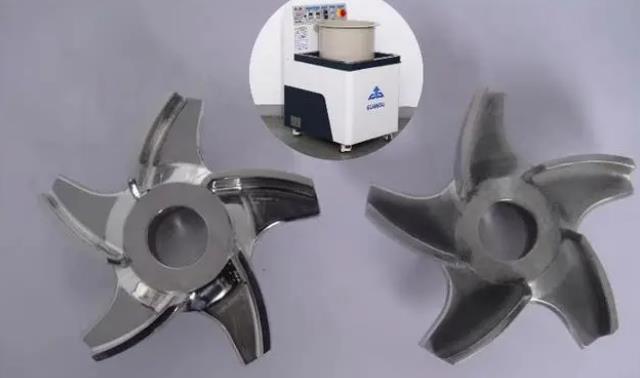

Effect of polishing irregular metal parts by magnetic grinder

Irregular metal parts are polished with magnetic lapping machines

Using magnetic grinder to polish irregular metal parts is a common polishing method. This method can quickly and effectively polish irregular metal parts and remove stains.

Magnetic grinding machine is mainly composed of magnetic system, rotor system and so on. The irregular metal parts are put into the polishing groove together with the magnetic abrasive particles. Through the rotation of the rotor system, the magnetic abrasive particles rotate along the surface of the part under the action of magnetic force, so as to polish and decontaminate the surface of the part.

Polishing effect of bending pipe

The advantage of using magnetic lapping machines to polish irregular metal parts is that it can achieve an efficient and uniform polishing effect, and can be used to polish irregular shaped parts. At the same time, the method can also reduce the labor intensity of workers and improve production efficiency.

However, when using a magnetic grinder to polish irregular metal parts, the following points need to be noted:

The shape and surface treatment of the part shall be suitable for polishing with a magnetic grinder.

The selection and addition of magnetic abrasive particles need to be controlled properly to avoid unnecessary damage to the surface of the parts.

In order to ensure the polishing effect and the normal operation of the machine, maintenance work such as cleaning and magnetic abrasive replacement in the polishing tank should be carried out in time.

In conclusion, magnetic lapping machines are a very effective polishing method that can provide a reliable surface treatment solution for the machining of irregular metal parts.

Wechat

Wechat